UNS S31803 Flange Suppliers / UNS S32205 Flange Suppliers | UNS S32750 Flange Suppliers | UNS S32760 Flange Suppliers | UNS S31254 Flange Suppliers

Super Duplex UNS S32750 Flanges | Super Duplex UNS S32760 Flanges | SMO 254 UNS S31254 Flanges Suppliers | Seamless Flanges | Welded Flanges | ASTM A182 Flanges | UNS S32205/ S31803 Flanges | UNS S31254 Flanges Manufacturer

Hex Tubes Inc are leading suppliers of Flanges in its various Grades, Forms and Shapes. We are an ISO 9001:2008 certified company which was founded in the year 2002. Since then we have rich experience of 16+ years in this field. We are well-known in industry as reliable suppliers of Flanges.

We are proud suppliers of Flanges in following grades:-

Flanges: – It is generally referred to a ridge or rim or plate which is either used internally or externally to support the component to hold its position in fixed position and helps in strengthening the joins of components with help of various types of applicable flanges.

And above Flanges grades are further available in following Forms, Methods and Shapes:-

Duplex UNS S31803 / UNS S32205 Flanges

Duplex 2205 Flanges | ASTM A182 | UNS S31803 | WNR 1.4462 | UNS S32205 Flanges Suppliers

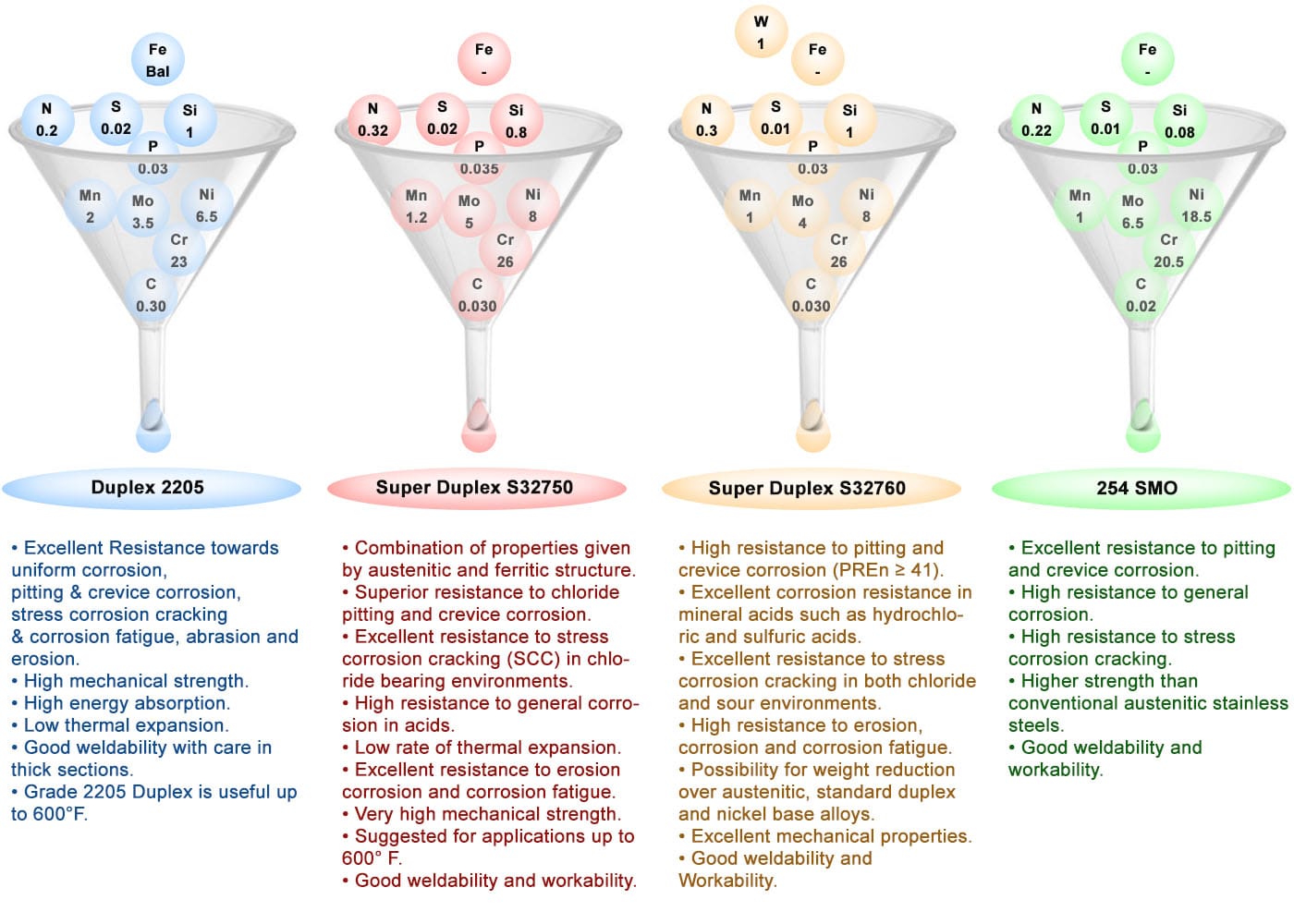

Duplex UNS S32205 alloy is equally ferritic and austenitic in nature, and hence a widely used grade of Stainless Steel. UNS S32205 consist of 22% Cr and 3% Mo, 5 to 6% Ni alloyed stainless steel.

In addition to high strength and excellent impact toughness, stress corrosion cracking resistance and high strength are exhibited by its Ferritic nature where as ease of fabrication and corrosion resistances are exhibited by its Austenitic nature. UNS S31803 Flanges has high applicability where demand for good corrosion resistance and good strength is required. In oxidizing, acidic and caustic environments, it exhibits good resistance towards pitting and crevice corrosion.

Duplex UNS S32205 Flanges are applicable in chemical processing, pulp and paper production, marine and other high chloride environments, Liquor tanks and paper machines, Transport and storage, Oil and gas exploration and processing equipments. Hex Tubes Inc has huge inventory of Duplex UNS S31803 Flanges in different standards and different dimensions, thickness and sizes. Hex Tubes Inc are proud 2205 Duplex UNS S32205 Stainless Steel Flanges Suppliers in following forms and shapes:-

| Types Of UNS S31803 / UNS S32205 Flanges | ||

|---|---|---|

|  |  |

| • UNS S31803 Blind Flange • UNS S32205 Raised Face Blind Flange • UNS S31803 Hub Blind Flange • UNS S32205 Spectacle Blind Flange • UNS S31803 Slip On Flange • UNS S32205 Slip On Raised Face Flange • UNS S31803 Slip On Flat Face Flange • UNS S32205 Threaded Flange • UNS S31803 Stainless Steel Threaded Flange | • UNS S31803 Socket Weld Flange • UNS S32205 Socket Weld Raised Face Flange • UNS S31803 Neck Weld Flange • UNS S32205 Stainless Steel Threaded Flange • UNS S31803 Orifice Flange • UNS S32205 Raised Face Weld Neck Flange • UNS S31803 Flat Face Slip On Flange • UNS S32205 Flat Face Flange • UNS S31803 Flat Face Weld Neck Flange | • UNS S31803 Ring Joint Flange • UNS S32205 Long Weld Neck Flange • UNS S31803 Raised Face Flange • UNS S32205 Neck Weld Flange • UNS S31803 Spectacle Flange • UNS S32205 Slop On Reducing Flange • UNS S31803 Tongue and Grove Flange • UNS S32205 Lapped Flange • UNS S31803 Reducing Weld Neck Flange |

Super Duplex UNS S32750 Flanges

Super Duplex S32750 Flanges | ASTM A182 | UNS S32750 | WNR 1.4410 | UNS S32750 Flanges Suppliers

Super Duplex UNS S32750 is equally ferritic and austenitic in nature and consists of 25% chromium, 4% molybdenum, and 7% nickel. It has a Pitting Resistance Equivalent Number (PREN) of >41 with excellent mechanical properties. UNS S32750 provides excellent resistance towards chloride stress corrosion cracking, pitting and crevice corrosion in almost all corrosive media.

Since its has been designed to be used in most demanding conditions where high strength and corrosion resistance are key factors, UNS S32750 Flanges is applicable at off-shore platforms, desalination plants, marine and other high chloride environments, chemical process pressure vessels, piping and heat exchangers, chemical Process Industries, oil and gas industry equipments.

Hex Tubes Inc has huge inventory of Super Duplex UNS S32750 Flanges in different standards and different dimensions, thickness and sizes. Hex Tubes Inc are proud UNS S32750 Flanges Suppliers in following forms and shapes:-

| Types of UNS S32750 Flanges | ||

|---|---|---|

|  |  |

| • UNS S32750 Blind Flange • UNS S32750 Raised Face Blind Flange • UNS S32750 Hub Blind Flange • UNS S32750 Spectacle Blind Flange • UNS S32750 Slip On Flange • UNS S32750 Slip On Raised Face Flange • UNS S32750 Slip On Flat Face Flange • UNS S32750 Threaded Flange • UNS S32750 Stainless Steel Threaded Flange | • UNS S32750 Socket Weld Flange • UNS S32750 Socket Weld Raised Face Flange • UNS S32750 Neck Weld Flange • UNS S32750 Stainless Steel Threaded Flange • UNS S32750 Orifice Flange • UNS S32750 Raised Face Weld Neck Flange • UNS S32750 Flat Face Slip On Flange • UNS S32750 Flat Face Flange • UNS S32750 Flat Face Weld Neck Flange | • UNS S32750 Ring Joint Flange • UNS S32750 Long Weld Neck Flange • UNS S32750 Raised Face Flange • UNS S32750 Neck Weld Flange • UNS S32750 Spectacle Flange • UNS S32750 Slop On Reducing Flange • UNS S32750 Tongue and Grove Flange • UNS S32750 Lapped Flange • UNS S32750 Reducing Weld Neck Flange |

Super Duplex UNS S32760 Flanges

Super Duplex S32760 Flanges | ASTM A182 | UNS S32760 | WNR 1.4410 | UNS S32760 Flanges Suppliers

Super Duplex UNS S32760 contains 25% Chromium, 4% Molybdenum, and 7% Nickel with addition of Copper and Tungsten. This composition helps in excellent corrosion resistance, designed for acid leach mining applications and other industries where sulfuric acid environments. Super Duplex UNS S32760 displays yield strength which is twice of 300 series SS. UNS S32760 is most cost effective than any other nickel alloys.

UNS S32760 Flanges is applicable in Pharmaceutical, Mining, Desalination, Pulp and paper, Power generation, Chemical process pressure vessels, piping and heat exchangers, Marine and other high chloride environments, Desalination plants, Off-shore platforms, Oil and Gas Industry equipments, and Chemical Process Industries.

Hex Tubes Inc has huge inventory of Super Duplex UNS S32760 Flanges in different standards and different dimensions, thickness and sizes. Hex Tubes Inc are proud UNS S32760 Flanges Suppliers in following forms and shapes:-

| Types of UNS S32760 Flanges | ||

|---|---|---|

|  |  |

| • UNS S32760 Blind Flange • UNS S32760 Raised Face Blind Flange • UNS S32760 Hub Blind Flange • UNS S32760 Spectacle Blind Flange • UNS S32760 Slip On Flange • UNS S32760 Slip On Raised Face Flange • UNS S32760 Slip On Flat Face Flange • UNS S32760 Threaded Flange • UNS S32760 Stainless Steel Threaded Flange | • UNS S32760 Socket Weld Flange • UNS S32760 Socket Weld Raised Face Flange • UNS S32760 Neck Weld Flange • UNS S32760 Stainless Steel Threaded Flange • UNS S32760 Orifice Flange • UNS S32760 Raised Face Weld Neck Flange • UNS S32760 Flat Face Slip On Flange • UNS S32760 Flat Face Flange • UNS S32760 Flat Face Weld Neck Flange | • UNS S32760 Ring Joint Flange • UNS S32760 Long Weld Neck Flange • UNS S32760 Raised Face Flange • UNS S32760 Neck Weld Flange • UNS S32760 Spectacle Flange • UNS S32760 Slop On Reducing Flange • UNS S32760 Tongue and Grove Flange • UNS S32760 Lapped Flange • UNS S32760 Reducing Weld Neck Flange |

SMO UNS S31254 Flanges

SMO 254 Flanges | ASTM A182 | UNS S31254 | WNR 1.4547 | UNS S31254 Flanges Suppliers

SMO UNS S31254 Flanges is a super austenitic stainless steel alloy, with very high end molybdenum and nitrogen content with low carbon content. Since it has Low carbon, hence less chance of carbide precipitation during heating. It exhibits good resistant to pitting and crevice corrosion, very high resistance to chloride stress, corrosion cracking, Excellent impact toughness and high ductility, Excellent workability and weldability.

It possesses lower coefficient of thermal expansion, and higher thermal conductivity. Also provides good general corrosion resistance and sulfide stress corrosion resistance. It is 50% stronger than 300-series austenitic stainless steels and has a Pitting Resistance Equivalent (PREN) of > 42.5.

UNS S31254 Flanges are applicable in Saltwater handling, Offshore oil and gas production equipments, Pulp mill bleach systems, Tall oil distillation columns, Desalination equipment, Flue gas desulphurization scrubbers, Food and chemical processing equipment, and Petroleum production.

Hex Tubes Inc has huge inventory of SMO UNS S31254 Flanges in different standards and different dimensions, thickness and sizes. Hex Tubes Inc are proud UNS S31254 Flanges Suppliers in following forms and shapes:-

| Types of UNS S31254 Flanges | ||

|---|---|---|

|  |  |

| • UNS S31254 Blind Flange • UNS S31254 Raised Face Blind Flange • UNS S31254 Hub Blind Flange • UNS S31254 Spectacle Blind Flange • UNS S31254 Slip On Flange • UNS S31254 Slip On Raised Face Flange • UNS S31254 Slip On Flat Face Flange • UNS S31254 Threaded Flange • UNS S31254 Stainless Steel Threaded Flange | • UNS S31254 Socket Weld Flange • UNS S31254 Socket Weld Raised Face Flange • UNS S31254 Neck Weld Flange • UNS S31254 Stainless Steel Threaded Flange • UNS S31254 Orifice Flange • UNS S31254 Raised Face Weld Neck Flange • UNS S31254 Flat Face Slip On Flange • UNS S31254 Flat Face Flange • UNS S31254 Flat Face Weld Neck Flange | • UNS S31254 Ring Joint Flange • UNS S31254 Long Weld Neck Flange • UNS S31254 Raised Face Flange • UNS S31254 Neck Weld Flange • UNS S31254 Spectacle Flange • UNS S31254 Slop On Reducing Flange • UNS S31254 Tongue and Grove Flange • UNS S31254 Lapped Flange • UNS S31254 Reducing Weld Neck Flange |

Looking for some more information ?

Get Best Quotes or Send us your Requirement

Documents

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight, gross weight, Marks & Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

Testings

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Packaging

The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

- Manufacturer’s Name or Trademark

- Material Designation

- Size Designation

- Rating Designation

- Melt Designation

- Marking for Identification

Leading Supplier, Manufacturer Exporter

More than 30 years of Experiance

Mill Test Report Provided

In Accordance with EN10204 NACE 3.1, NACE 3.2

Fast Delivery

Warehouse near to Airport & Port.

Efficient & Cost Effective Shipping Services

We Offer EXW – Ex Works, FOB, CFR, CIF, DDU, etc.

Inspection

3rd Party Inspection is Carried out

ISO 9001:2008 Certified

Quality Product

Transparent client dealing, No False Assurance, 100% Fulfillment of Commitments.

Worldwide Exporter

Export to more than 70 Countries Worldwide

Best Price

Competitive pricing is offered