254 SMO Pipe Suppliers | 254 SMO Seamless Pipe Suppliers | 254 SMO Welded Pipe Suppliers | 254 SMO ERW Pipe Manufacturers | 6Mo Pipe Suppliers | ASTM A312 UNS S31254 Pipes | WNR 1.4547

SMO 254 Pipes Suppliers | SMO 254 Pipes Manufacturers | 254 SMO Pipes Exporters | ASTM A312 SMO 254 Pipes Stockist | UNS S31254 Pipes Suppliers | WNR 1.4547 SMO 254 Pipes | 6MO Pipes Suppliers | 254 SMO Stainless Steel Pipes | 6 Moly Pipes Suppliers

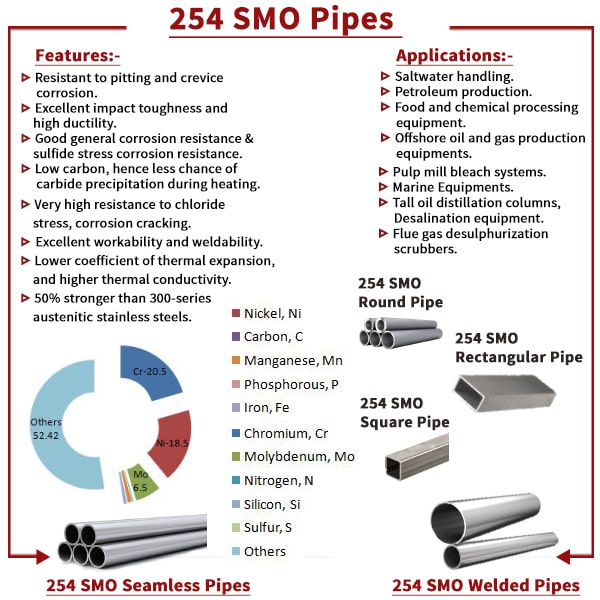

Alloy 254 also known as 254 SMO alloy, 6Mo alloy, 6 Moly alloy, or 254 SMO Super Austenitic Stainless Steel alloy. 254 SMO alloy is intentionally designed with high molybdenum content in its chemical composition, to achieve exclusive properties like impact toughness, resistance towards pitting corrosion, fatigue corrosion and crevice corrosion, and chloride stress cracking. 6 Mo alloy is also twice as strong as rest of 300 series stainless steels. Hence 6 Moly alloy is highly in demand for applications demanding good strength and impact toughness, resistance towards corrosive and oxidation medias and use under extreme temperatures.

Hex Tubes Inc are proud 254 SMO Pipe Suppliers all over the globe in more them 70+ countries, in its various forms like Seamless, Welded, ERW etc and its various shapes like Round, Rectangle, Square which adhere to all international standards and specifications. We are proud UNS S31254 Pipe Suppliers.

254 SMO Seamless Pipe Suppliers | 254 SMO Welded Pipe Suppliers | UNS S31254 Pipe Suppliers | WNR 1.4547 SMO 254 Pipe | 6Mo Stainless Steel Pipes | 254 SMO ERW Pipes | 6 Moly Pipes

Hex Tubes Inc are well known as 254 SMO Pipe Suppliers all over the globe. We also take huge pride in being UNS S31254 Seamless Pipe Suppliers, UNS S31254 Welded Pipe Suppliers and UNS S31254 ERW Pipe Suppliers.

254 SMO Pipes are built to possess excellent resistance to Corrosive and Oxidations environments even under extreme temperature range.

Addition of Nickel and Copper to ASTM A312 254 SMO Pipes provides very good resistance towards pitting corrosion and crevice corrosion in environments containing halide ions like chloride ions, fluoride ions and bromide ions solutions. UNS S31254 Pipes display good weldability.

Hex Tubes Inc offers wide spectrum of high-quality, durable and extreme corrosion resistance WNR 1.4547 UNS S31254 Seamless Pipes, WNR 1.4547 UNS S31254 Welded Pipes, WNR 1.4547 UNS S31254 ERW Pipes in various sizes, specifications and shapes. UNS 31254 Pipes are available in following size range,

for UNS S31254 Seamless Pipes – 1/8″ NB to 36″ NB,

for UNS S31254 Welded Pipes – 1/8″ NB to 48″ NB,

and UNS S31254 ERW Pipes – 1/8″ NB to 48″ NB.

We also Provide them in 6Mo Round Pipes(254 SMO Round Pipes suppliers), 6Mo Rectangle Pipes (254 SMO Rectangle Pipes suppliers) and 6Mo Square Pipes (254 SMO Square Tubes suppliers)shapes.

Hex Tubes Inc also take custom orders for UNS S31254 Pipes at request. We also provide associated services which includes the likes of welding, cutting, polishing, electro polishing, shot blasting etc.

Hex Tubes Inc offers all SMO 254 Pipes like SMO 254 Seamless Pipes, SMO 254 Welded Pipes and SMO 254 ERW Pipes as per international standards and specifications like NACE 3.1 certification, mili test certification and ISO certifications approved by government of India lab. We also conduct positive material identification on all the raw materials available at Hex Tubes Inc.

Exclusive characteristics of 254 SMO Pipes (6 Mo Pipes or 6 Moly Pipes) make them highly applicable in applications like marine environments, brackish water, bleaching operations, closed loop water systems and some food processing applications.

Generally UNS S31254 Pipes are applicable in saltwater handling, petroleum production, pulp mill bleach systems, flue gas desulphurization scrubbers, food and chemical processing equipment’s, offshore oil and gas production equipment’s, tall oil distillation columns, desalination equipment’s.

Since ASTM A312 S31254 Welded Tubes are applicable in severe corrosive environments, their welding process should be done under clean and careful conditions to ensure the retention of corrosion characteristics of weld metal and heat affected zones. No subsequent heat treatment is required if welding is done without preheating. Manual metal-arc welding with covered electrodes and gas-shielded arc welding, mainly by means of the TIG and MIG methods are some suitable methods of fusion welding.

Specification:

| Standard | ASTM A 269 ASME SA 269, ASTM A 249 ASME SA 249, UNS 31254 piping |

| Seamless Pipe Size | 3.35 mm OD To 101.6 mm OD |

| Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg |

| Pipe wall thickness | 0.020″ –0.220″, (special wall thicknesses available) |

| Length | Single Random, Double Random, Standard & Cut length pipe |

| Finish | Polished, Annealed & Pickled (AP), Bright & Annealed (BA), MF |

| Form | U-bent or Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc. |

| Type | Seamless, ERW, EFW, Welded, Fabricated pipes |

| End | Plain End, Beveled End, Treaded pipes |

Hex Tubes Inc are proud 254 SMO Pipes suppliers, which are applicable in Oil pipes, Gas pipes, Fluid pipes, Boiler pipes, Heat exchanger pipes.

Alloy 254 Stainless Steel Pipes provided at our company are given with Value Added Service like Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc.

All 6Mo Pipes are marked with following informations – Standard, Grade, OD, Thickness, Length, Heat No., We also provide custom marking or according to the customer’s request.

Hex Tubes Inc specializes in 254 SMO Capillary Pipes, 254 SMO Heat Exchanger Pipes, 254 SMO Condenser Pipes, 254 SMO Instrumentation Pipes, 254 SMO High Pressure Pipes, 254 SMO Coiled Pipes, 254 SMO Capilary Pipes, 254 SMO Exhaust Pipes, 254 SMO Gas Pipes, 254 SMO Seamless Pipes, 254 SMO Welded Pipes, 254 SMO Round Pipes, 254 SMO Square Pipes, 254 SMO Rectangular Pipes & 254 SMO Pipes.

Hex Tubes Inc also provide all kinds of Test Certificates like Manufacturer Test Certificate, Laboratory Test Certificate from Govt. Approved Lab, Under Third Party Inspection etc etc.

Types of SMO 254 Pipes:-

| SMO 254 Pipes | SMO 254 Seamless Pipes | SMO 254 Round Seamless Pipes SMO 254 Square Seamless Pipes SMO 254 Rectangle Seamless Pipes |

| SMO 254 Welded Pipes | SMO 254 Round Welded Pipes SMO 254 Square Welded Pipes SMO 254 Rectangle Welded Pipes |

|

| SMO 254 ERW Pipes | SMO 254 Round ERW Pipes SMO 254 Square ERW Pipes SMO 254 Rectangle ERW Pipes |

254 SMO Seamless Pipes Suppliers | SMO 254 Seamless Pipe Suppliers | 6Mo Seamless Pipes Suppliers

A solid round billet of 254 SMO alloy is heated at certain temperature and pushed with pressure over a sharp piercing object to form a cylindrical hollow pipe spread across the longitudinal stretch. The pipe formed through this process is known as 254 SMO Seamless Pipes (UNS S31254 Seamless Pipes) which consist of no weld or seam or any joints, as a result these 6Mo Seamless Pipes have higher load bearing capacity and high stress capacity. 6Moly Seamless Pipes do not have any weld throughout its length along its cross-section. Due to its making process, SMO 254 Seamless Pipes exhibits excellent roundness and ovality as compared to its welded counterpart.

Hex Tubes Inc are leading 254 SMO Seamless Pipes Exporters all over globe. We are specialized 254 SMO Seamless Pipes Manufacturers and UNS S31254 Seamless Pipes Suppliers. We are popular 254 SMO Seamless Pipe Stockist, as we have huge inventory of wide range of SMO 254 Seamless Pipes in following size range for UNS S31254 Seamless Pipes – 1/8″ NB to 36″ NB.

254 SMO Seamless Pipes are further available in Round (254 SMO Round Seamless Pipes suppliers), Rectangle (254 SMO Rectangle Seamless Pipes suppliers) and Square (254 SMO Square Seamless Pipes suppliers) shapes.

6 Mo Seamless Pipe Suppliers

Other Names:- UNS S31254 Seamless Pipes, WNR 1.4547 SMO 254 Seamless Pipes, ASTM A312 UNS S31254 Seamless Pipes, ASTM A213 , ASTM A269, 6Mo Seamless pipes, 6 Molybdenum Seamless Pipes.

254 SMO Welded Pipe Suppliers | SMO 254 Welded Pipe Suppliers | 6Mo Welded Pipe Suppliers

A flat strip or sheet or plate of 254 SMO alloy is pressurized into desired cylindrical hollow pipe spread across the longitudinal stretch. This pipe is then pressed again for the either ends of sheet to meet and welded together using high energy welding source like an electric arc, laser beam, plasma arc, electron beam etc. Then is it allowed to cool and solidify, thereby forming a 254 SMO Welding Pipe. This 6Mo Welded Pipes contains weld or seam or joint, and hence are cheaper than its counterpart Seamless Pipes and hence more in demand and readily available. The wall thickness of 6Moly Welded Pipes is more consistent than its counterpart. Inner surface of UNS S31254 Welded Pipes can be checked and cleaned before manufacturing then, which is not possible in seamless pipes.

Hex Tubes Inc are leading 254 SMO Welded Pipes Exporters all over globe. We are specialized 254 SMO Welded Pipes Manufacturers and UNS S31254 Welded Pipes Suppliers. We are popular 254 SMO Welded Pipe Stockist, as we have huge inventory of wide range of SMO 254 Welded Pipes in following size range for UNS S31254 Welded Pipes – 1/8″ NB to 48″ NB.

254 SMO Welded Pipes are further available in Round (254 SMO Round Welded Pipes suppliers), Rectangle (254 SMO Rectangle Welded Pipes suppliers) and Square (254 SMO Square Welded Pipes suppliers) shapes.

6 Mo Welded Pipe Suppliers

Other Names:- UNS S31254 Welded Pipes, WNR 1.4547 SMO 254 Welded Pipes, ASTM A312 UNS S31254 Welded Pipes, ASTM A213, ASTM A249, ASTM A358,ASTM A409, 6Mo Welded Pipes, 6 Molybdenum Welded Pipes.

254 SMO ERW Pipe Suppliers | SMO 254 ERW Pipes Suppliers | 6Mo ERW Pipes Suppliers

A flat strip or sheet or plate of 254 SMO alloy is pressurized into desired cylindrical hollow pipe spread across the longitudinal stretch. This pipe is then pressed again for the either ends of sheet to meet and welded together using ERW or Electric Resistance Welding. This tubes are called as 254 SMO ERW Pipes. This process is usually used for higher diameters and for cost cutting as its cheapest available process. 6Mo ERW Tubes have a seam or weld over its cross section. 6Moly ERW Pipes are welded longitudinally. SMO 254 ERW Pipes are available in various wall thickness, diameter, qualities and finishes.

Hex Tubes Inc are leading 254 SMO ERW Pipes Exporters all over globe. We are specialized 254 SMO ERW Pipes Manufacturers and 254 SMO ERW Pipes Suppliers. We are popular 254 SMO ERW Pipes Stockist, as we have huge inventory of wide range of SMO 254 Welded Pipes in following size range for UNS S31254 ERW Pipes – upto 24″ OD.

UNS S31254 ERW Pipes are further available in UNS S31254 Round Pipes (254 SMO Round ERW Pipes suppliers), UNS S31254 Rectangle Pipes (254 SMO Rectangle ERW Pipes suppliers) and UNS S31254 Square Pipes (254 SMO Square ERW Pipes suppliers) shapes.

SMO 254 ERW Pipe

Other Names:- UNS S31254 ERW Tubes, WNR 1.4547 SMO 254 ERW Tubes, ASTM A312 UNS S31254 ERW Tubes, ASTM A213, ASTM A249, ASTM A358,ASTM A409

ASTM A312 UNS S31254 Pipes Forms

Other Names:-

-

- 254 smo pipes

- 254 smo seamless pipes

- 254 smo welded pipes

- 254 smo erw pipes

- 254 smo round pipes

- 254 smo rectangle pipes

- 254 smo square pipes

- 254 smo hollow pipes

- 254 smo piping

- 254 smo stainless steel pipes

- smo 254 pipes

- smo 254 seamless pipes

- smo 254 welded pipes

- smo 254 erw pipes

- smo 254 round pipes

- smo 254 rectangle pipes

- smo 254 square pipes

- smo 254 hollow pipes

- smo 254 piping

- smo 254 stainless steel pipes

- 6Mo pipes

- 6Mo seamless pipes

- 6Mo welded pipes

- 6Mo erw pipes

- 6Mo round pipes

- 6Mo rectangle pipes

- 6Mo square pipes

- 6Mo hollow pipes

- 6Mo piping

- 6Mo stainless steel pipes

- UNS S31254 pipes

- UNS S31254 seamless pipes

- UNS S31254 welded pipes

- UNS S31254 erw pipes

- UNS S31254 round pipes

- UNS S31254 rectangle pipes

- UNS S31254 square pipes

- UNS S31254 hollow pipes

- UNS S31254 piping

- UNS S31254 stainless steel pipes

- ASTM A312 UNS S31254 pipes

- ASTM A312 UNS S31254 seamless pipes

- ASTM A312 UNS S31254 welded pipes

- ASTM A312 UNS S31254 erw pipes

- ASTM A312 UNS S31254 round pipes

- ASTM A312 UNS S31254 rectangle pipes

- ASTM A312 UNS S31254 square pipes

- ASTM A312 UNS S31254 hollow pipes

- ASTM A312 UNS S31254 piping

- ASTM A312 UNS S31254 stainless steel pipes

- wnr 1.4547 6Mo pipes

- wnr 1.4547 6Mo seamless pipes

- wnr 1.4547 6Mo welded pipes

- wnr 1.4547 6Mo erw pipes

- wnr 1.4547 6Mo round pipes

- wnr 1.4547 6Mo rectangle pipes

- wnr 1.4547 6Mo square pipes

- wnr 1.4547 6Mo hollow pipes

- wnr 1.4547 6Mo piping

- wnr 1.4547 6Mo stainless steel pipes

- din 1.4547 6Mo pipes

- din 1.4547 6Mo seamless pipes

- din 1.4547 6Mo welded pipes

- din 1.4547 6Mo erw pipes

- din 1.4547 6Mo round pipes

- din 1.4547 6Mo rectangle pipes

- din 1.4547 6Mo square pipes

- din 1.4547 6Mo hollow pipes

- din 1.4547 6Mo piping

- din 1.4547 6Mo stainless steel pipes

- 254 smo pipes suppliers

- 254 smo seamless pipes suppliers

- 254 smo welded pipes suppliers

- 254 smo erw pipes suppliers

- 254 smo round pipes suppliers

- 254 smo rectangle pipes suppliers

- 254 smo square pipes suppliers

- 254 smo hollow pipes suppliers

- 254 smo piping suppliers

- 254 smo stainless steel pipes

suppliers

Characteristics of SMO 254 Stainless Steel

- High Resistance to uniform corrosion.

- High Resistance to pitting & crevice corrosion.

- High Resistance to stress corrosion cracking & corrosion fatigue

- High mechanical strength

- High Resistance to abrasion & erosion

- High Resistance to Fatigue

- High energy absorption

- Low thermal expansion

- Good weld ability with care in thick sections

- Useful up to 600°F

Applications of SMO 254 Stainless Steel

- Chemical Processing Industry – Transport and Storage, pressure vessels, tanks, piping, and heat exchangers.

- Oil and Gas exploration and processing equipment – piping, tubing, and heat exchangers

- Marine Industry and Seawater systems – Cargo Tanks for Ships, High chloride environments,

- FGD / Effluent Scrubber Systems.

- Paper and Pulp Industry Digesters, Bleaching equipment and Stock-Handling Systems, Chip Pre-steaming vessels.

- Food Processing Equipment.

- Flue gas desulfurization / cleaning equipment

- Rotors, fans, shafts, and press rolls requiring combined strength and corrosion resistance

- Biofuels Plant, Desalination plants

- Firewalls and blast walls on offshore platforms

254 SMO Pipe Suppliers | 254 SMO Pipe Manufacturers | 254 SMO Pipe Stockist | 254 SMO Pipe Exporters

| Grade | Type | Unified Numbering System (UNS) | Forgings Grades | Werkstoff-nr. | Euronorm | AFNOR | DIN Standards | |

|---|---|---|---|---|---|---|---|---|

| No. | Name | |||||||

| 6Mo grade | 254 SMO | S31254 | F44 | 1.4547 | en 1.4547 | FeMi35Cr20Cu4Mo2 | Z1 CNDU 20.18.06Az | din 1.4547 |

| Material SMO Steel | Tube Specification |

|---|---|

| SMO UNS S31254 Steel Tube | ASTM A312 / A358 / A813 / A814 A269 / A213 / A249 / A270 |

| SMO UNS S31254 Steel Seamless Tube | ASTM A269, A213, A312 |

| SMO UNS S31254 Steel Welded Tube | ASTM A249, A269 , A312, A358, A409 |

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

| Density (Kg.m-1) | 8000 |

| Magnetic Permeability | <1.05 |

| Young’s Modulus (N/mm2) | 200 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 500 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.85 |

| Thermal conductivity, 20°C | 13.5 |

Looking for some more information ?

Get Best Quotes or Send us your Requirement

Popular names for 254 SMO Pipes –

6Mo Pipes

6Moly Pipes

254 SMO Pipes

SMO 254 Pipes

UNS S31254 Pipes

WNR 1.4547 6Mo Pipes

Din 1.4547 6Moly Pipes

ASTM A312 SMO 254 Pipes

254 SMO Stainless Steel Pipes

6Mo Stainless Steel Pipes

6Mo Seamless Pipes

6Moly Seamless Pipes

254 SMO Seamless Pipes

SMO 254 Seamless Pipes

UNS S31254 Seamless Pipes

WNR 1.4547 6Mo Seamless Pipes

Din 1.4547 6Moly Seamless Pipes

ASTM A312 SMO 254 Seamless Pipes

254 SMO Stainless Steel Seamless Pipes

6Mo Stainless Steel Seamless Pipes

6Mo Welded Pipes

6Moly Welded Pipes

254 SMO Welded Pipes

SMO 254 Welded Pipes

UNS S31254 Welded Pipes

WNR 1.4547 6Mo Welded Pipes

Din 1.4547 6Moly Welded Pipes

ASTM A312 SMO 254 Welded Pipes

254 SMO Stainless Steel Welded Pipes

6Mo Stainless Steel Welded Pipes

6Mo ERW Pipes

6Moly ERW Pipes

254 SMO ERW Pipes

SMO 254 ERW Pipes

UNS S31254 ERW Pipes

WNR 1.4547 6Mo ERW Pipes

Din 1.4547 6Moly ERW Pipes

ASTM A312 SMO 254 ERW Pipes

254 SMO Stainless Steel ERW Pipes

6Mo Stainless Steel ERW Pipes

Documents

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight, gross weight, Marks & Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

Testings

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Packaging

The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

- Manufacturer’s Name or Trademark

- Material Designation

- Size Designation

- Rating Designation

- Melt Designation

- Marking for Identification

Leading Supplier, Manufacturer Exporter

More than 30 years of Experiance

Mill Test Report Provided

In Accordance with EN10204 NACE 3.1, NACE 3.2

Fast Delivery

Warehouse near to Airport & Port.

Efficient & Cost Effective Shipping Services

We Offer EXW – Ex Works, FOB, CFR, CIF, DDU, etc.

Inspection

3rd Party Inspection is Carried out

ISO 9001:2008 Certified

Quality Product

Transparent client dealing, No False Assurance, 100% Fulfillment of Commitments.

Worldwide Exporter

Export to more than 70 Countries Worldwide

Best Price

Competitive pricing is offered