Super Duplex S32750 Flange | Super Duplex Stainless Steel 2507 Flange | ASTM A182 | ANSI B 16.5 | Super Duplex Flanges Suppliers | Super Duplex Flanges Manufacturers | UNS S32750 Flanges

Super Duplex 2507 Flange | Super Duplex 2507 Flange Slip-On | Super Duplex 2507 Raised Face Slip On Flange | Super Duplex 2507 Slip-On Reducing Flange | Super Duplex 2507 Weld Neck Reducing Flange | Flat Face Weld Neck Flange | Stainless Steel Weld Neck Flange | Raised Face Weld Neck Flange | Weld Neck Reducing Flange | Lap Joint Flange | Raised Flange | A182 | B16.5 | Girth Flange | Tongue And Groove Flange | Neck Flange | Blind Flange Raised Face | Reducing Flange Weld Neck

Flange RF | WNRF Flange | Flange WN | WNRF | FF Flange | RFWN Flange | SW Flange | BLRF Flange | Flange SORF | Flange SO | SWRF Flange | SOFF Flange | LWNRF Flange | LJ Flange | FFSO Flange | NB Flange | RTJ Weld Neck Flange | FFWN Flange

Hex Tubes Inc a leading manufacturer, exporter, and supplier of Super Duplex Stainless Steel (1.4410) Flange (ASTM A182 / ANSI B16.5). Hex Tubes Inc offers a complete range of Super Duplex S32750 (A182 F53) Flange such as Super Duplex Blind Flange, Super Duplex Slip On Flange, Super Duplex S32750 Slip On Raised Face (SORF Flange), Super Duplex S32750 Slip On Flat Face Flange (SOFF Flange), Super Duplex S32750 Lap Joint Flange (LJ Flange), Super Duplex S32750 Weld Neck Flange (WN Flange), Super Duplex S32750 Weld Neck Raised Flange (WNRF Flange), Super Duplex S32750 Threaded Flange, Super Duplex S32750 Socket Weld Flange, Super Duplex S32750 Socket Weld Raised Face (SWRF) Flange, Super Duplex S32750 Raised Face Weld Neck Flange (RFWN Flange), Super Duplex S32750 Reducing Flange, Super Duplex S32750 Flat Face Flange (FF Flange), Super Duplex S32750 Flat Face Slip On Flange (FFSO Flange), Super Duplex S32750 Flat Face Weld Neck (FFWN), Super Duplex S32750 Ring Joint Flange, Super Duplex S32750 Long Weld Neck Flange (LWNRF Flange), Super Duplex S32750 Plate Flange, Super Duplex S32750 Raised Face Flange (RF Flange), Super Duplex S32750 Orifice Flange, Super Duplex S32750 Spectacle Flange and Super Duplex S32750 Spectacle Blind Flange. We are one of the leading Stainless Steel Flange Manufacturer (Stainless Steel Flange Manufacturer) who can weld Super Duplex S32750 Flange (A182 F53) in various sizes and dimensions. They have special quality finishing and duress for long life, high pressure, and zero defects.

All Super Duplex S32750 Flange (F53 UNS S32750) are offered with NACE 3.1 Certification, Mill Test Certification, and ISO 17025 Standards by a Government of India approved Laboratory. Positive Material Identification is done on all raw material procured at Hex Tubes Inc. Super Duplex S32750 (A182 F55) Flange (ASTM A182 / ANSI B16.5) can be manufactured and supplied in a variety of sizes and pressure ratings to meet project specific requirements of our customers. Our Super Duplex (1.4410) Steel Flange are widely supplied to many industries including boiler manufacturing, brewing tanks, and desalination plants.

UNS S32750 Flange (ASTM A182 / ANSI B16.5) are generally lower in cost, as a lower percentage of alloying element is used in the manufacturing of Super Duplex S32750 Flange. The yield strength of Super Duplex Stainless Steel (A182 F53) Flange is higher compared to austenitic stainless steel flange, as a result of which users can purchase relatively lower thickness Super Duplex Stainless Steel (UNS S32750) Flange.

Hex Tubes Inc also stocks and supplies a complete range of Stainless Steel S32750 Flange (ASTM A182 / ANSI B16.5) like Super Duplex S32750 Blind Flange, Super Duplex S32750 Slip On Flange, Super Duplex S32750 Lap Joint Flange (LJ Flange), Super Duplex S32750 Weld Neck Flange (WN Flange), Super Duplex S32750 Weld Neck Raised Flange (WNRF Flange), Super Duplex S32750 Threaded Flange, Super Duplex S32750 Slip On Flat Face Flange (SOFF Flange), Super Duplex S32750 Flat Face Slip-On (FFSO Flange), Super Duplex S32750 Pipe Flange, Super Duplex S32750 Socket Weld Flange, Super Duplex S32750 Socket Weld Raised Face (SWRF) Flange, Super Duplex S32750 Reducing Flange, Flat Face Flange (FF Flange), Super Duplex S32750 Ring Joint Flange, Super Duplex S32750 Long Weld Neck Flange (LWNRF Flange), Super Duplex S32750 Plate Flange, Super Duplex S32750 Raised Face Flange (RF Flange), Super Duplex S32750 Raised Face Weld Neck Flange (RFWN Flange), Super Duplex S32750 Orifice Flange, Super Duplex S32750 Slip On Raised Face (SORF Flange), Super Duplex S32750 Spectacle Flange and Super Duplex S32750 Spectacle Blind Flange to complement our existing production range of Super Duplex S32750 (A182 F53) Flange. Super Duplex Stainless Steel (1.4410) Flange (ASTM A182 / ANSI B16.5) are used in Petro-Chemical Industry, Oil and Gas Industry, Nuclear Industry, Pulp & Paper Industry, Research & Development, Mega Projects & Defense & Development Industries.

Super Duplex S32750 (1.4410) Flange Specification:-

Specifications: ASTM A182, ASME SA182, F53 (A182 F53), ANSI B16.5, ANSI B16.47, ANSI B16.48 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings.

Dimensions : DIN, ASTM, BS and all International Standards.

Size : ½” (15 NB) to 48″ (1200NB).

Grade : EN 1.4410, UNS S32750.

Pressure Rating : Class 150, Class 300, Class 400, Class 600, Class 900, Class1500, Class 2500 | PN6, PN10, PN16, PN25, PN40, PN64 etc.

Types : Super Duplex S32750 Blind Flange, Super Duplex S32750 Slip On Flange, Super Duplex S32750 Lap Joint Flange (LJ Flange), Super Duplex S32750 Weld Neck Flange (WN Flange), Super Duplex S32750 Threaded Flange, Super Duplex S32750 Socket Weld Flange, Super Duplex S32750 Socket Weld Raised Face (SWRF) Flange, Super Duplex S32750 Slip On Raised Face (SORF Flange), Super Duplex S32750 Slip On Flat Face Flange (SOFF Flange), Super Duplex S32750 Raised Face Weld Neck Flange (RFWN Flange), Super Duplex S32750 Weld Neck Raised Flange (WNRF Flange), Super Duplex S32750 Reducing Flange, Super Duplex S32750 Flat Face Flange (FF Flange), Superr Duplex S32750 Flat Face Slip On (FFSO Flange), Super Duplex S32750 Flat Face Weld Neck (FFWN), Super Duplex S32750 Ring Joint Flange, Super Duplex S32750 Long Weld Neck Flange (LWNRF Flange), Super Duplex S32750 Plate Flange, Super Duplex S32750 Raised Face Flange (RF Flange), Super Duplex S32750 Orifice Flange, Super Duplex S32750 Spectacle Flange and Super Duplex S32750 Spectacle Blind Flange.

Our Super Duplex Stainless Steel (UNS S32750) Flange conforms to NACE MR0175/ISO 15156.

Types of Super Duplex S32750 Pipe Flange

- Super Duplex S32750 Weld Neck Reducing Flange

- Super Duplex S32750 Flat Face Weld Neck Flange

- Super Duplex S32750 Neck Weld Flange

- Super Duplex S32750 Weld Neck Flange Raised Face

- Super Duplex S32750 Weld Neck Flange

- Super Duplex S32750 Raised Face Weld Neck Flange

- Super Duplex S32750 Lapped Flange

- Super Duplex S32750 Raised Face Flange

- Super Duplex S32750 Tongue And Groove Flange

- Super Duplex S32750 Slip Flange

- Super Duplex S32750 Reducing Weld Neck Flange

- Super Duplex S32750 Stainless Steel Threaded Flange

- Super Duplex S32750 Flange

- Super Duplex S32750 Hub Blind Flange

- Super Duplex S32750 Blind Flange

- Super Duplex S32750 Flange Slip-On

- Super Duplex S32750 Slip-On Raised Face Flange

- Super Duplex S32750 Slip-On Reducing Flange

- Super Duplex S32750 Socket Weld Flange

- Super Duplex S32750 Lap Joint Flange

- Super Duplex S32750 Threaded Flange

- Super Duplex S32750 Flat Face Flange

- Super Duplex S32750 Spectacle Flange

- Super Duplex S32750 Orifice Flange

- Super Duplex S32750 Long Neck Flanges

- Super Duplex S32750 Reducing Flange

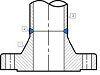

Super Duplex S32750 Weld Neck Flange

Welding Neck Flange or Weldneck Flange (WN Flange) are easy to recognize at the long tapered hub, that goes gradually over to the wall thickness from a pipe or fitting. The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and/or elevated temperatures. The smooth transition from flange thickness to pipe or fitting wall thickness affected by the taper is extremely beneficial, under conditions of repeated bending, caused by line expansion or other variable forces.

Super Duplex S32750 Weld Neck Flange (WN Flange)

1. Super Duplex S32750 Weld Neck Flange 2. Super Duplex S32750 Butt Weld Flange 3. Super Duplex S32750 Pipe or Fitting Flange

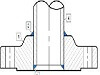

UNS S32750 Slip On Flange (SO Flange)

1. Super Duplex S32750 Slip-On flange 2. Super Duplex S32750 Filled weld outside Flange 3. Super Duplex S32750 Filled weld inside Flange 4. Super Duplex S32750 Pipe Flange.

Super Duplex S32750 Slip On Flange (SO Flange)

The calculated strength from a Slip-On flange (SO Flange) under internal pressure is of the order of two-thirds that of Welding Neck flange, and their life under fatigue is about one-third that of the latter. The connection with the pipe is done with 2 fillet welds, as well as the outside of the flange. The X measure on the image is approximately Wall thickness of pipe + 3 mm. This space is necessary, to do not damage the flange face, during the welding process.

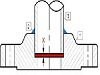

Super Duplex S32750 Socket Weld Flange (SW Flange)

Super Duplex S32750 Socket Weld flanges were initially developed for use on small-size high-pressure piping. Their static strength is equal to Slip On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges. The connection with the pipe is done with 1 fillet weld, at the outside of the flange. But before welding, some space must be created between flange or fitting and pipe.

UNS S32750 Socket Weld Flange (SW Flange)

1. Super Duplex S32750 Socket Weld flange 2. Super Duplex S32750 Filled weld Flange 3. Pipe X = Expansion gap

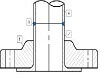

Super Duplex S32750 Lap Joint Flange (LJ Flange)

1. Super Duplex S32750 Lap Joint flange 2. Sper Duplex S32750 Stub End 3. Super Duplex S32750 Butt weld 4. Pipe or Fitting

Lap Joint Flange (LJ Flange)

Lap Joint Flange have all the same common dimensions as any other flange named on this page however it does not have a raised face, they used in conjunction with a “Lap Joint Stub End”. These flanges are nearly identical to a Slip-On flange with the exception of a radius at the intersection of the flange face and the bore to accommodate the flanged portion of the Stub End. Their pressure-holding ability is little, if any, better than that of Slip-On flange and the fatigue life of the assembly is only one-tenth that of Welding Neck flanges.

Threaded Flange

Stainless Steel Threaded Flange are used for special circumstances with their main advantage being that they can be attached to the pipe without welding. Sometimes a seal weld is also used in conjunction with the threaded connection. Although still available in most sizes and pressure ratings, screwed fittings today are used almost exclusively in smaller pipe sizes. A threaded flange or fitting is not suitable for a pipe system with thin wall thickness, because cutting threads on a pipe is not possible.

Super Duplex 2507 Threaded Flange

1. Super Duplex 2507 Threaded flange 2. Super Duplex S32750 Thread Flange 3. Pipe or Fitting

Duplex UNS S32750 Blind Flange (BL Flange)

Super Duplex S32750 Blind Flange (BL Flange)

Super Duplex S32750 Blind Flange are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flange, particularly in the larger sizes, are the most highly stressed flange types. However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure-temperature applications.

Super Duplex S32750 Flat Face Flange (FF Flange)

The Flat Face (FF) flange has a gasket surface in the same plane as the bolting circle face. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting. These pipe flanges are used when the counter-flanges are flat faced. They are mainly used to connect to cast iron equipment, valves, and specialties. This flat face flange has a gasket surface in the same plane as the bolting circle face. Flat face flanges are never to be bolted to a raised face flange. ASME B31.1 says that when connecting flat face cast iron flanges to carbon steel flanges, the raised face on the carbon steel flange must be removed and that a full face gasket is required. This is to keep the thin, brittle cast iron flange from being sprung into the gap caused by the raised face of the carbon steel flange.

Super Duplex S32750 Flat Face Flange (FF Flange)

Super Duplex S32750 Face Flange (RF Flange)

Raised Face Flange (RF Flange)

These pipe flanges are the most commonly used flanges. The raised face thickness for 150# and 300# are included in the specified flange thickness and for higher rating, they are not included in the flange thickness. The Raised Face (RF) type is the most applied flange face and is easy to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face.

Tongue And Groove Flange

Tongue And Groove Flange pipe flange is more reliable type of flange joint but is costlier than the other type of flange. The Tongue And Groove faces of these flanges must be matched. One flange face has a raised ring (Tongue) machined onto the flange face while the mating flange has a matching depression (Groove) machined into the face. Tongue And Groove facings are standardized in both large and small types. Tongue And Groove Flange differ from male-and-female in that the inside diameters of the tongue-and-groove do not extend into the flange base, thus retaining the gasket on its inner and outer diameter.

F53 Tongue And Groove Flange

Super Duplex Ring Type Joint (RTJ) Flange

Ring Type Joint (RTJ) Flange

These pipe flanges are the most reliable type of flange joint but are costlier than the other type of flange.The Ring Type Joint flange are generally used in high pressure (Class 600 and higher rating) and/or high-temperature services above 800°F (427°C). A flange is a forged or cast ring of steel designed to connect sections of pipe or join pipe to a pressure Vessel, pump or any other integral flange assembly.

Super Duplex S32750 Spectacle Flange

This is a pressure retaining plate with one solid end and one open end connected with a web or tie-bar. In normal operation, the open end forms the seal between two flanges and permits normal flow of fluid through pipework. If the solid end is swung into position it effectively blanks of the pipe and halts the flow.

Super Duplex S32750 Spectacle Flanges

Super Duplex UNS S32750 Orifice Flanges

Orifice Flange

The function of an orifice flange is to provide access to a line for metering of gasses or liquids. An orifice plate is clamped between a pair of the flange when installing in a line and the whole assembly is referred to as an orifice flange union. Jack-screws within the assembly facilitates removal of the orifice plate. The orifice plate, the metering device, consists of a thin plate with a concentric, square edge, circular hole in the center. Two pressure tap-holes are drilled in each flange to measure pressure difference through the orifice.

Super Duplex S32750 Long Neck Flange

Owing to our rich industrial experience, we are offering a comprehensive range of Long Weld Neck Flange. The professionals of our organization source these neck Flange from trusted vendors. These Flanges are unique due to their simple connectivity with other pipes. Moreover, our products are extensively used in refining industries for linking purposes. Our esteemed patrons can avail these qualitative range of Flange from us at industry-leading prices.

Super Duplex S32750 Long weld Neck Flange

Super Duplex S32750 Reducing Flange

Super Duplex S32750 Reducing Flange

Super Duplex Reducing Flange is used in place of standard Flange to allow for a change in pipe size. The flange consists of one specified diameter with a smaller diameter bore size. Except for the bore and hub dimensions, a reducing flange has dimensions of the larger pipe size. Welding neck, slip-on, and threaded Flange can be reducers and are considered an economical means to make a pipe size transition. Reducing Slip On Flange, Reducing Weld Neck Flange.

Super Duplex Flanges:-

- Super Duplex Flange Suppliers

- Super Duplex Flange Manufacturers

- Super Duplex Flange Stockist

- Super Duplex Flange Exporters

- Super Duplex S32750 Flange Suppliers

- Super Duplex S32750 Flange Manufacturers

- Super Duplex S32750 Flange Stockist

- Super Duplex S32750 Flange Exporters

- UNS S32750 Flange Suppliers

- UNS S32750 Flange Manufacturers

- UNS S32750 Flange Stockist

- UNS S32750 Flange Exporters

- WNR 1.4410 UNS S32750 Flange Suppliers

- WNR 1.4410 UNS S32750 Flange Manufacturers

- WNR 1.4410 UNS S32750 Flange Stockist

- WNR 1.4410 UNS S32750 Flange Exporters

| Grade | Type | Unified Numbering System (UNS) | Forgings Grades | Werkstoff-nr. | Euronorm | AFNOR | DIN Standards | |

|---|---|---|---|---|---|---|---|---|

| No. | Name | |||||||

| 2507 | Super Duplex | S32750 | F53 | 1.4410 | en 1.4410 | X2CrNiMoN25-7-4 | Z3CN25.06Az | din 1.4462 |

Characteristics of Super Duplex UNS S32750 Flange

- High Resistance to uniform corrosion.

- High Resistance to pitting & crevice corrosion.

- High Resistance to stress corrosion cracking & corrosion fatigue

- High mechanical strength

- High Resistance to abrasion & erosion

- High Resistance to Fatigue

- High energy absorption

- Low thermal expansion

- Good weld ability with care in thick sections

- Useful up to 600°F

Applications of Super Duplex UNS S32750 Flange

- Chemical Processing Industry – Transport and Storage, pressure vessels, tanks, piping, and heat exchangers.

- Oil and Gas exploration and processing equipment – piping, tubing, and heat exchangers

- Marine Industry and Seawater systems – Cargo Tanks for Ships, High chloride environments,

- FGD / Effluent Scrubber Systems.

- Paper and Pulp Industry Digesters, Bleaching equipment and Stock-Handling Systems, Chip Pre-steaming vessels.

- Food Processing Equipment.

- Flue gas desulfurization / cleaning equipment

- Rotors, fans, shafts, and press rolls requiring combined strength and corrosion resistance

- Biofuels Plant, Desalination plants

- Firewalls and blast walls on offshore platforms

- Super Duplex 2507 Chemical Composition

- Super Duplex 2507 Mechanical Properties

- Super Duplex 2507 Physical Properties

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| UNS S32750 | 0.030 Max | 24.0-26.0 | 1.20 Max | 3.0-5.0 | 6.0-8.0 | 0.24-0.32 | 0.035 Max | 0.80 Max | 0.020 Max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 550[79.8] |

|---|---|

| Tensile Strength (N/mm2) [ksi] minimum | 800 [116] |

| Elongation (%) minimum | 25 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 45 |

| Density (Kg.m-1) | 7810 |

| Magnetic Permeability | 33 |

| Young’s Modulus (N/mm2) | 199 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 475 |

| Fracture Toughness, Kq (MPa.m) | 475 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.80 |

| Thermal conductivity, 20°C | 14.2 |

| Mean coefficient of thermal expansion | 11.1 x 10-6 |

Looking for some more information ?

Get Best Quotes or Send us your Requirement

Documents

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight, gross weight, Marks & Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

Testings

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Packaging

The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

- Manufacturer’s Name or Trademark

- Material Designation

- Size Designation

- Rating Designation

- Melt Designation

- Marking for Identification

Leading Supplier, Manufacturer Exporter

More than 30 years of Experiance

Mill Test Report Provided

In Accordance with EN10204 NACE 3.1, NACE 3.2

Fast Delivery

Warehouse near to Airport & Port.

Efficient & Cost Effective Shipping Services

We Offer EXW – Ex Works, FOB, CFR, CIF, DDU, etc.

Inspection

3rd Party Inspection is Carried out

ISO 9001:2008 Certified

Quality Product

Transparent client dealing, No False Assurance, 100% Fulfillment of Commitments.

Worldwide Exporter

Export to more than 70 Countries Worldwide

Best Price

Competitive pricing is offered