254 SMO Wiremesh | SMO 254 Wiremesh | WNR 1.4547 UNS S31254 Wiremesh | 6Mo Wiremesh

254 SMO Wiremesh Supplier | 254 SMO Wiremesh Manufacturer | 254 SMO Wiremesh Exporter | 254 SMO Wiremesh Stockist

254 SMO Wire Mesh | 254 SMO Weld Mesh | 254 SMO Wire Mesh Fence | 254 SMO Fencing Wire Mesh | 254 SMO Welding Wire | 254 SMO Mesh Sheet | 254 SMO Tie Wire | 254 SMO Spring Wire | 254 SMO Welded Wire Mesh Rolls | 254 SMO Plain Dutch Weave | 254 SMO Reverse Twill Dutch Weave | 254 SMO Welded Wire Mesh Fence | 254 SMO Woven Stainless Steel Mesh

Hex Tubes Inc is well known and famous as 254 SMO Wiremesh Suppliers all over the globe. We specialize as UNS S31254 Wiremesh Suppliers which are manufactured with high precision and very high quality. 254 SMO Wiremesh are also known as 6Mo Wiremesh suppliers. These 6Moly Wiremesh adhere to all the international standards and specifications and hence accepted all over the world with high demand. In order to provide the highest quality standard of SMO 254 Wiremesh to our clients, we at Hex Tubes Inc follow a stringent quality control process. Hex Tubes Inc is a global industry-leading provider of 254 SMO Wiremesh solutions and have obtained ASME Quality and ISO 9001:2008 Certifications.

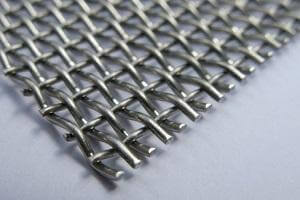

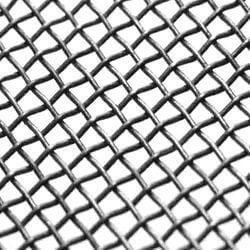

254 SMO Welded Wiremesh | 254 SMO Woven Wiremesh

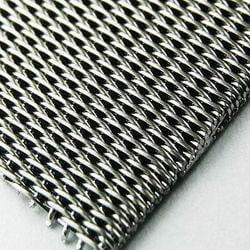

Hex Tubes Inc is proud of being 254 SMO Wiremesh Suppliers all over the globe in more then 70+ countries. Since 6Moly Wiremesh is most demanded product due to its high strength and extensive corrosion resistance towards the chloride stress corrosion cracking. Other then Chloride SSC (Stress Corrosion Cracking) , 6Moly Wiremesh also offers good resistance towards pitting and crevice corrosion along with natural corrosion as well. It also displays good conductivity of heat and shows gives minor coefficient of expansion. 254 SMO Stainless Steel WIremesh is famous for exhibiting excellent anti corrosive properties and excellent mechanical strength.

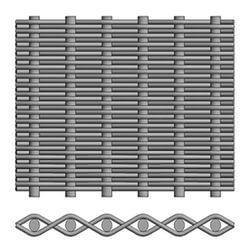

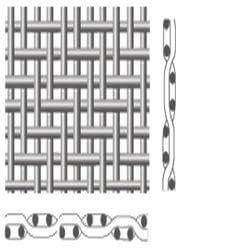

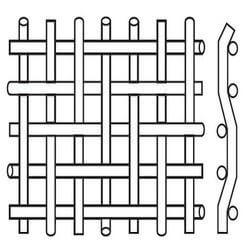

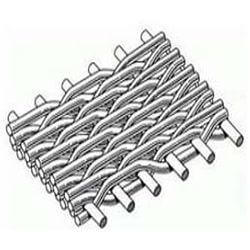

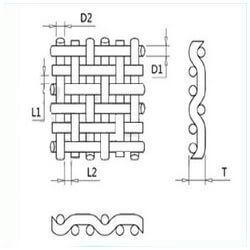

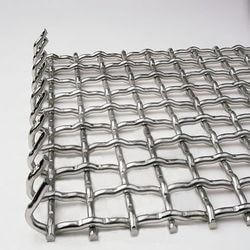

Hex Tubes Inc provides 254 SMO Wiremesh in two different forms like welded wiremesh and woven wiremesh which are available in three patterns like plain weave pattern, dutch weave pattern and twill weave pattern. These weave patterns are futher available in following forms like Plain Dutch Wire Mesh, Reverse Dutch Wire Mesh, Twill Dutch Wiremesh, Reverse Twill Dutch Wire Mesh, Dutch Twill Weave, Twill Dutch Weave, Cross Twill Weave , Crimped Wire Mesh. These 254 SMO Wiremesh are suitable for oil and air hardening as they exhibit great hardness maintainance.

254 SMO Wire Mesh Types

254 SMO Welded Wire Mesh

Welded wire mesh, or welded wire mesh fence, or “weldmesh” is an electric fusion welded prefabricated joined grid consisting of a series of parallel longitudinal wires with accurate spacing welded to cross wires at the required spacing. The stainless steel welded wire mesh is a metal wire screen that is made up of low carbon steel wire or stainless steel wire. Welded Stainless Steel Mesh is available in various sizes and shapes. Welded Stainless Steel wire Mesh is widely used in agricultural, industrial, transportation, horticultural and food procuring sectors.

SS Welded Wire Mesh is also used in mines, gardening, machine protection and other decorations.Stainless Steel Welded Wire Mesh is the term given to the kind of barrier fencing that is manufactured in square or rectangular mesh from steel wire, welded at each intersection. Welded wire mesh is also sometimes used in reinforced concrete, notably for slabs.

254 SMO Woven Wire Mesh

Woven Wire Mesh a mesh is often defined as a loosely woven or knitted fabric that has a large number of closely spaced holes. Knitted mesh is frequently used for modern sports jerseys and other clothing. Stainless Steel Woven Wire Mesh is being used widely within various types of industries, mostly for processing purposes where foods or non-foods need to be dried, filtered or transported. On the other side, woven wire mesh Stainless Steel can also be used for fences and decoration of buildings.

Hex Tubes Inc manufactures various types of wire mesh weave patterns, however the most common weaves are for example Plain, Dutch and Twill weave. The other Types of Woven Wire Mesh are crimped wire mesh, reverse dutch, reverse twill dutch, cross teill weave, dutch twill weave, three heddle, five heddle, twill dutch weave, for each type of demand can be a different kind of woven wire mesh designed and manufactured. This really depends on the type of industry and the purpose of the end product.

Hex Tubes Inc has huge inventory of 254 SMO Wiremesh in different forms, sizes, patterns, customized daimeters, and wall thickness at the most competetive price. We offers our customers with geniune quality 254 SMO Wiremesh products which adhere to all domestic and international standards like BIS, BSS, ASTM, TYLER and DIN standards and regulations.

Hex Tubes Inc is one of the largest WNR 1.4547 254 SMO Stainless Steel Wire Mesh Manufacturers and UNS S31254 254 SMO Stainless Steel Wire Mesh Suppliers. Hex Tubes Inc has a wide Range if 254 SMO Industrial Wire Mesh such as Stainless Steel Welded Wire Mesh, SS Welded Wire Mesh, Welded Stainless Steel Wire Mesh, Weld Mesh, Welded Wire Mesh Rolls, Wire Netting, Stainless Steel Wire Netting, Mesh Fencing, Wire Mesh Fencing, Stainless Steel Wire Fencing, Welded Wire Mesh Fence, SS Welded Wire Mesh, Wire Mesh Fence, Stainless Steel Welding Wire, Stainless Steel Woven Wire Mesh, Woven Stainless Steel Mesh, Woven Stainless Steel Wire Mesh, Woven Wire Mesh Stainless Steel, Steel Wire Mesh, Mesh Wire, SS Wire Mesh, Fencing Wire Mesh, Stainless Steel Tie Wire, Stainless Steel Wire Mesh Sheets.

| Grades | 254 SMO, EN 1.4547, UNS S31254. |

| Types of Weave Wire Mesh | Plain Weave, Twill Weave, Dutch Weave, Plain Dutch Wire Mesh, Reverse Dutch Wire Mesh, Reverse Twill Dutch Wire Mesh, Cross Twill Weave, Dutch Twill Weave, Twill Dutch Weave. |

| Size | 10 mm To 100 mm Dia in 100 mm TO 6000 mm Length. |

| End | Wire (Coil Form), Wire-mesh, Billet, Ingot, Forging Etc. |

| Surface Finishing | NA |

| Our 254 SMO Wiremesh | conforms to NACE MR0175/ISO 15156. |

254 SMO Wire and 254 SMO Mesh supplied by our company Hex Tubes Inc, have a number of great features such as Low maintenance, Fine construction, Smooth finish, and so on. Our 6Mo UNS S31254 Steel Wires are exclusively considered for their sturdy built quality and dimensional accuracy required for constructions. Due to their durable nature, WNR 1.4547 SMO 254 Steel Wires are highly applicable in constructions.

Hex Tubes Inc is well known UNS S31254 Wiremesh Suppliers in its various forms like UNS S31254 Wire Mesh, UNS S31254 Weld Mesh, UNS S31254 Wire Mesh Fence, UNS S31254 Fencing Wire Mesh, UNS S31254 Welding Wire, UNS S31254 Mesh Sheet, UNS S31254 Tie Wire, UNS S31254 Spring Wire, UNS S31254 Welded Wire Mesh Rolls, UNS S31254 Plain Dutch Weave, UNS S31254 Reverse Twill Dutch Weave, UNS S31254 Welded Wire Mesh Fence, UNS S31254 Woven Stainless Steel Mesh.

254 SMO Wire Mesh Forms

- 254 SMO Plain Weave

- 254 SMO Twill Weave

- 254 SMO Dutch Weave

- 254 SMO Plain Dutch Wire Mesh

- 254 SMO Reverse Dutch Wire Mesh

- 254 SMO Reverse Twill Dutch Wire Mesh

- 254 SMO Cross Twill Weave

- 254 SMO Dutch Twill Weave

- 254 SMO Twill Dutch Weave

- 254 SMO Crimped Wire Mesh

- 254 SMO Reverse Dutch Weave

- 254 SMO Reverse Twill Dutch Weave

- 254 SMO Three Heddle Weave

- 254 SMO Five Heddle Weave

- 254 SMO Wire Mesh

- 254 SMO Wire

Corrosion properties of 254 SMO Wiremesh:

Generally the conventional stainless steel are easily attacked by local forms of corrosion like crevice corrosion, pitting corrosion, or stress corrosion cracking when exposed to halides containing environments like bromide ions and chloride ions. When exposed to environments containing acid, the presence of halides promotes and boosts general corrosion.

In sulphuric acid environments, 254 SMO Round Wiremesh posses higher resistant than SS 316, and in naturally aerated sulphuric acid containing chloride ions environments 254 SMO Wiremesh exhibits higher resistance than SS 904L.

Due to the higher nickel and molybdenum content resistance towards Stress Corrosion Cracking (SSC) is higher in 254 SMO Round Bars as compared to TP 304 or TP 316 which are prone to SSC at temperatures above 60 C.

During welding or heating, there is very little risk of carbide precipitation due to very low carbon content. Welding can be done without any risk of intergranular corrosion.

The PRE value (which is = >42.5) displays 254 SMO Round Wiremesh possess excellent resistance towards pitting and crevice corrosion.

254 SMO Round Wiremesh shows excellent bending and machining properties. It also possesses excellent impact strength from room temperature and cryogenic temperatures. 6Mo Round Wiremesh has good weldability properties. Manual Metal Arc welding and Gas Shielded Arc welding are suitable methods of fusion welding.

Excellent resistance towards pitting and crevice corrosion, PRE >= 42.5

254 SMO Steel Wire Mesh Properties

254 SMO Steel Wire Mesh Applications

254 SMO Wire Mesh Supplier | 254 SMO Wire Mesh Manufacturer | 254 SMO Wire Mesh Exporter | 254 SMO Wire Mesh Stockist

Hex Tubes Inc is a 254 SMO Stainless Steel Wire Mesh suppliers, 254 SMO Crimped Wire Mesh suppliers, 254 SMO Stainless Steel Wire suppliers, Wire Mesh supplier in singapore, 254 SMO Stainless Steel Wire Mesh supplier, 254 SMO Stainless Steel Wire Mesh machine suppliers, Wire Mesh supplier in uae, 254 SMO Stainless Steel mesh manufacturers, welded Wire Mesh manufacturers usa, Wire Mesh manufacturers, welded Wire Mesh manufacturers california, 254 SMO Stainless Steel tie wire manufacturers, 254 SMO Stainless Steel wire cloth manufacturers, welded Wire Mesh manufacturer, steel wire neting manufacturers, 254 SMO Stainless Steel Wire Mesh manufacturer, welded Wire Mesh, manufacturers,, plain weave Wire Mesh, manufacturers, 254 SMO Stainless Steel Wire Mesh suppliers, crimped Wire Mesh suppliers, 254 SMO Stainless Steel wire suppliers, Wire Mesh supplier in singapore, 254 SMO Stainless Steel Wire Mesh supplier, 254 SMO Stainless Steel Wire Mesh machine suppliers, Wire Mesh supplier in uae, 254 SMO Stainless Steel mesh manufacturers, welded Wire Mesh manufacturers usa, Wire Mesh manufacturers, welded Wire Mesh manufacturers california, 254 SMO Stainless Steel tie wire manufacturers, 254 SMO Stainless Steel wire cloth manufacturers, welded Wire Mesh manufacturer, steel wire neting manufacturers, 254 SMO Stainless Steel Wire Mesh manufacturer, welded Wire Mesh manufacturers, plain weave Wire Mesh manufacturers, 254 SMO Wire Mesh in India, 254 SMO Wire Mesh in United Arab Emirates, 254 SMO Wire Mesh in UAE, 254 SMO Wire Mesh in Abu Dhabi, 254 SMO Wire Mesh in Dubai, 254 SMO Wire Mesh in United Kingdom, 254 SMO Wire Mesh in UK, 254 SMO Wire Mesh in England, 254 SMO Wire Mesh in London, 254 SMO Wire Mesh in United States, 254 SMO Wire Mesh in US, 254 SMO Wire Mesh in California, 254 SMO Wire Mesh in Texas, 254 SMO Wire Mesh in New York, 254 SMO Wire Mesh in Georgia, 254 SMO Wire Mesh in New Jersey, 254 SMO Wire Mesh in Australia, 254 SMO Wire Mesh in Brazil, 254 SMO Wire Mesh in Canada, 254 SMO Wire Mesh in France, 254 SMO Wire Mesh in Germany, 254 SMO Wire Mesh in Greece.

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

| Density (Kg.m-1) | 8000 |

| Magnetic Permeability | <1.05 |

| Young’s Modulus (N/mm2) | 200 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 500 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.85 |

| Thermal conductivity, 20°C | 13.5 |

Looking for some more information ?

Get Best Quotes or Send us your Requirement

Documents

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight, gross weight, Marks & Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

Testings

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Packaging

The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

- Manufacturer’s Name or Trademark

- Material Designation

- Size Designation

- Rating Designation

- Melt Designation

- Marking for Identification

Leading Supplier, Manufacturer Exporter

More than 30 years of Experiance

Mill Test Report Provided

In Accordance with EN10204 NACE 3.1, NACE 3.2

Fast Delivery

Warehouse near to Airport & Port.

Efficient & Cost Effective Shipping Services

We Offer EXW – Ex Works, FOB, CFR, CIF, DDU, etc.

Inspection

3rd Party Inspection is Carried out

ISO 9001:2008 Certified

Quality Product

Transparent client dealing, No False Assurance, 100% Fulfillment of Commitments.

Worldwide Exporter

Export to more than 70 Countries Worldwide

Best Price

Competitive pricing is offered