254 SMO | Super Austenitic Stainless Steel | UNS S31254 | WNR 1.4547 | 6Mo | 6 Molybdenum | SMO 254

254 SMO, UNS S31254, WNR 1.4547, 6Mo, 6 Molybdenum, 254 SMO Stainless Steel , SMO 254

254 SMO Stainless Steel alloy is also known as 6mo Stainless Steel alloy (6Mo) or 6 Molybdenum Stainless Steel alloy. 254 SMO is a metal with high Molybdenum content. It is an on-purpose developed high alloy austenitic stainless steel, exclusively applicable in saline water and other aggressive chloride containing environments applications.

SMO 254 Alloy is a Molybdenum and Nitrogen alloyed Super Austenitic Stainless Steel Alloy with low Carbon content in its chemical composition.

The combination of Nickel and Copper in its chemical composition provides 254 SMO with high impact toughness resistance towards chloride stress corrosion cracking, towards pitting and crevice corrosion. It also provides it with strength that is twice that of the 300 series stainless steel alloys, especially in environments which contains halides ions, e.g. chloride ions, bromide ions and fluoride ions solutions, where conventional stainless steels can be easily attacked by local corrosion in the form of pitting corrosion, crevice corrosion or stress corrosion cracking. Presence of halides in acidic environments results in accelerated general corrosion.

Due to its austenitic microstructure, 6 Molybdenum SMO possesses excellent impact strength both at room temperature as well as at cryogenic temperatures.

6Mo (ck3mcun) also exhibits high ductility and impact strength. Due to high levels of Chromium, Molybdenum and Nitrogen in its chemical composition, UNS S31254 SMO Stainless Steel is highly applicable in environments with high chloride content like saline water, pulp mills, beach plants, brackish water, etc. UNS S31254 Stainless Steel fulfills all the requirements even at -196C as per European standards. For the austenitic steels, resistance to Stress Corrosion Cracking increases with higher nickel and molybdenum contents.

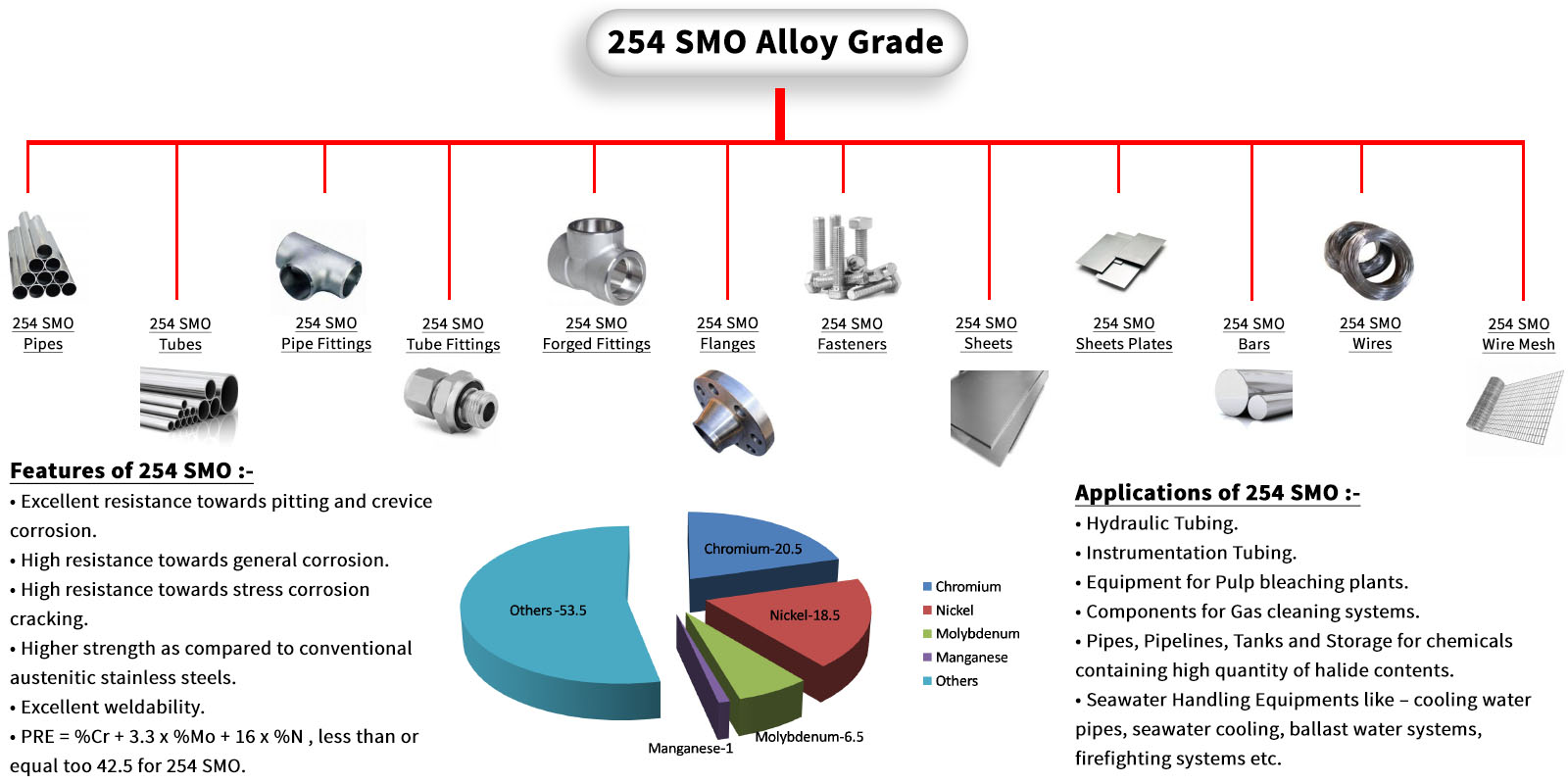

The PRE (Pitting Resistance Equivalent) is defined as a parameter for comparing the resistance towards pitting in chloride environments, which is defined by equation in weight-%, PRE = %Cr + 3.3 x %Mo + 16 x %N

PRE-value for 254 SMO = ≥ 42.5.

Mo 6 is considered as an cost-effective substitute for all high nickle alloys or titanium alloys, and hence is popularly applicable in various applicaions. 6 Moly exhibits excellent workability and is easily Fabricated and Weldability properties, and is compatible with the common Austenitic Stainless Steels.

254 SMO possesses higher resistance than Stainless Steel 316 in pure sulphuric acid environments, and in naturally aerated sulphuric acid environments containing chloride ions 254 SMO displays higher resistance than Stainless Steel 904L.

254 SMO has very little risk of carbide precipitation during heating, as it contains very low carbon content. It passes the Strauss test even after sensitizing for one hour at 600–1000 C temperatures. 254 SMO should not be exposed for longer periods at temperatures 600 – 1000 C as intermetallic phases are precipitated at given temperatures. As a result this kinds of precipitations do not contain any type of risk of intergranular corrosion. This is usefull during welding and it can be carried out without any risk of intergranular corrosion.

The 254 SMO products like tubes are delivered in heat treated condition. If case of further process is required to heat treatment, then solution annealing at temperatures 1150–1200°C (2100–2190°F), quenching in water is recommended . Thin-walled tubes min. 1130°C (2060°F), quenching in air/water.

254 SMO displays excellent welding properties. Welding should be done without preheating (if performed correctly, no subsequent heat treatement is required). Fusion welding is carried out by manual metal arc welding with covered electrodes and gad shield shield arc welding by TIG and MIG methods.

As 254 SMO alloys is targeted towards application resistance to severe corrosive environments, welding must be done with through cleaning so the weld metal and heat affected areas are maintained with best possible corrosion characteristics.

Welding heat input shouldn’t surpass 1.5Kj per mm, and during multipass welding the interpass temperatures shouldn’t surpass 100.

A stringer bead welding technique should be used.

The welding technique ” stringer bead welding” can be used, which usually enrolls a risk of hot-cracking in the weld metal. But Hex Tubes Inc provides a very high degree of purity of 254 SMO alloy, hence the risk of this type of cracking is significantly reduced.

Hex Tubes Inc is one of the leading and famous 254 SMO Exporter, 254 SMO Supplier, and 254 SMO Manufacturer of Super Austenitic Stainless Steel 254 SMO (UNS 31254 / SMO 254 / 6Mo) to various exclusive heavy industries in India and other 70+ countries. Hex Tubes Inc has grown exponentially in the field of Industrial Supplies offering a wide range of 254 SMO Stainless Steel suppliers in forms like 254 SMO Pipe (ASTM A312), 254 SMO Tube, 254 SMO Pipe Fittings (ASTM A403), 254 SMO Tube Fittings, 254 SMO Forged Fittings (ASTM A473 F44), 254 SMO Flange (ASTM A182 F44), 254 SMO Fasteners, 254 SMO Bar, 254 SMO Sheet, 254 SMO Plate, 254 SMO Wiremesh.

Hex Tubes Inc is loaded with the necessary tools, machines, and equipment which help us manufacture large consignments within stipulated timeframes to our clients. We provide 254 SMO products which abide all international standards and specifications. Every unit of consignment is individually inspected and tested, thereby elimanating any chance of anomaly.

Our UNS S31254 SMO / Mo 6 Stainless Steel (SS254 / SMO Material) Products are used by several European, Africa, and Gulf-based companies.

Hex Tubes Inc certified by ISO 9001: 2008 for evergrowing excellence in providing pure quality Super Austenitic 254 SMO Stainless Steel (UNS 31254 / SMO 254 / 6Mo Stainless Steel) products to its clients. Hex Tubes Inc has exponential grown within past with respect to quality & quantity. Hex Tubes Inc is most famous and well-recognized and trusted brand, since the ever growing demand of 254 SMO Stainless Steel (1.4547 / F44 Material) products throughout the world. Today we’re catering the demand of our renowned Companies around the world.

Hex Tubes Inc is a global supplier of 254 SMO Supplier in India, 254 SMO Supplier in UAE, 254 SMO Supplier in Abu Dhabi, 254 SMO Supplier in Dubai, 254 SMO Supplier in UK, 254 SMO Supplier in England, 254 SMO Supplier in London, 254 SMO Supplier in US, 254 SMO Supplier in California, 254 SMO Supplier in Texas, 254 SMO Supplier in New York, 254 SMO Supplier in Georgia, 254 SMO Supplier in New Jersey, 254 SMO Supplier in Australia, 254 SMO Supplier in Brazil, 254 SMO Supplier in Canada, 254 SMO Supplier in France, 254 SMO Supplier in Germany, 254 SMO Supplier in Greece, 254 SMO Supplier in Indonesia, 254 SMO Supplier in Italy, 254 SMO Supplier in Malaysia, 254 SMO Supplier in Netherland, 254 SMO Supplier in Philippines, 254 SMO Supplier in Russia, 254 SMO Supplier in Saudi Arabia, 254 SMO Supplier in Singapore, 254 SMO Supplier in South Africa, 254 SMO Supplier in South Korea, 254 SMO Supplier in Spain, 254 SMO Supplier in Sweden, 254 SMO Supplier in Thailand, 254 SMO Supplier in Ukraine.

6 Molybdenum Stainless Steel (SMO 254) Forms

- 254 SMO Seamless Pipe

- 254 SMO Welded Pipe

- 254 SMO Seamless Tube

- 254 SMO Welded Tube

- 254 SMO Steel Bar

- 254 SMO Square Bar

- 254 SMO Hex Bar (Hexagon Bar)

- 254 SMO Flat Bar

- 254 SMO Round Bar

- 254 SMO Threaded Bar

- 254 SMO Hollow Bar

- 254 SMO Wire

- 254 SMO Wire Mesh

- 254 SMO Twill Weave Wire Mesh

- 254 SMO Dutch Weave Wire Mesh

- 254 SMO Blind Flange

- 254 SMO Slip On Flange

- 254 SMO Lap Joint Flange

- 254 SMO Weld Neck Flange

- 254 SMO Threaded Flange

- 254 SMO Socket Weld Flange

- 254 SMO Sheet

- 254 SMO Plate

- 254 SMO Bolts

- 254 SMO Screw

- 254 SMO Nuts

- 254 SMO Washer

- 254 SMO Socket Weld Fittings

- 254 SMO Threaded Fittings

254 SMO Pipe Fittings / Buttweld Fittings

- 254 SMO Elbow

- 254 SMO Tee

- 254 SMO Reducer

- 254 SMO Couplings

- 254 SMO Stub Ends

- 254 SMO Cross

- 254 SMO Pipe Bends

- 254 SMO Pipe Nipples

254 SMO Compression Tube Fittings

- 254 SMO Union

- 254 SMO Connector

- 254 SMO Elbow

- 254 SMO Tee

- 254 SMO Adapter

- 254 SMO End Reducer

- 254 SMO Plug

- 254 SMO Cap

- 254 SMO Nut

- 254 SMO Ferrule

Types of 254 SMO products provided by Hex Tubes Inc :-

254 SMO Pipes

Hex Tubes Inc are proud 254 SMO Pipe suppliers all over the globe. SMO 254 Pipes are further available in 254 SMO Seamless Pipes (WNR 1.4547 Seamless Pipes) and 254 SMO Welded Pipes (WNR 1.4547 Welded Pipes).

ASTM Seamless Pipes are without seam or weld and hence can withstand high amount of pressure and stress as compared to ASTM Welded Pipes.

UNS S31254 Welded Pipes has a welded seam, which provides it with lower operating pressure as compared to its counterpart 6Mo Seamless Pipes. But they posses tighter dimensional tolerance as compared to UNS S31254 Seamless Pipes.

We are well-know as 254 SMO Seamless Pipes Suppliers and 254 SMO Welded Pipes Suppliers with huge invetory of different sizes and shapes of 6MO Pipes.

Other Names :- 254 SMO Pipe, UNS S31254 Pipe, WNR 1.4547 Pipe, ASTM B166 Pipe, 6Mo Pipe, SMO Alloy 254 Pipe, SMO Stainless Steel 254 Pipe

254 SMO Tubes

Hex Tubes Inc are proud 254 SMO Tube suppliers all over the globe. SMO 254 Pipes are further available in 254 SMO Seamless Tubes (WNR 1.4547 Seamless Tubes) and 254 SMO Welded Tubes (WNR 1.4547 Welded Tubes).

ASTM Seamless Tubes are without seam or weld and hence can withstand high amount of pressure and stress as compared to ASTM Welded Tubes.

UNS S31254 Welded Tubes has a welded seam, which provides it with lower operating pressure as compared to its counterpart 6Mo Seamless Tubes. But they posses tighter dimensional tolerance as compared to UNS S31254 Seamless Tubes.

We are well-know as 254 SMO Seamless Tubes Suppliers and 254 SMO Welded Tubes Suppliers with huge invetory of different sizes and shapes of 6MO Tubes.

Other Names :- 254 SMO Tube, UNS S31254 Tube, WNR 1.4547 Tube, ASTM B166 Tube, 6Mo Tube, SMO Alloy 254 Tube, SMO Stainless Steel 254 Tube

254 SMO Pipe Fittings

Hex Tubes Inc are proud 254 SMO Pipe Fittings suppliers or 254 SMO Buttweld Fittings suppliers all over the globe. SMO 254 Pipe Fittings are further available in 254 SMO Long Radius Elbow, SMO 254 Short Radius Elbow, 254 SMO WNR 1.4547 Long Radius Return Bend, 254 SMO UNS S31254 Short Radius Return Bend, 6Mo Reducing Elbow, 254 SMO End Cap, SMO Alloy 254 Stub Ends, 254 SMO Pipe Nipple, 254 SMO Equal Tee, 254 SMO Unequal Tee, 254 SMO Pipe Cross, 254 SMO Reducing Cross, 254 SMO Cross, 254 SMO Concentric Reducer, SMO Stainless Steel 254 Eccentric Reducer, 254 SMO pipe Collar, 254 SMO Pipe Coupling.

254 SMO Buttweld Fittings are used to join two or more pipes, therby extending the un-interrupted flow of content within. 254 SMO Pipe Fittings also provides strength to the joints with help of additional force to maintain strength and stability. 6MO Pipe Fittings add another characteristic by helping to change the direction of flow of the content along with smooth flow.

Other Names :- SMO 254 Pipe Fittings, UNS S31254 Pipe Fittings, WNR 1.4547 Pipe Fittings, ASTM B166 Pipe Fittings, 6Mo Pipe Fittings, SMO Alloy 254 Pipe Fittings, SMO Stainless Steel 254 Pipe Fittings, SMO 254 Buttweld Fittings, UNS S31254 Buttweld Fittings, WNR 1.4547 Buttweld Fittings, ASTM B166 Buttweld Fittings, 6Mo Buttweld Fittings, SMO Alloy 254 Buttweld Fittings, SMO Stainless Steel 254 Buttweld Fittings.

254 SMO Tube Fittings

Hex Tubes Inc are proud 254 SMO Tube Fittings suppliers or 254 SMO Compression Fittings suppliers all over the globe. SMO 254 Ferrule Fittings are further available in SMO 254 Compression Tube Fittings, SMO 254 Tube Fittings, SMO 254 Compression Fittings, SMO 254 Fittings. We offers SMO 254 Compression Fittings in all standard sizes and forms like 254 SMO Female Connector, 254 SMO Blanking Plug, 254 SMO Blanking End, 254 SMO Union Cross, 254 SMO Back Ferrule, 254 SMO Female Run Tee, 254 SMO Tube Nut, 254 SMO Street Tee, 254 SMO Female Elbow, 254 SMO Female Adapter.

254 SMO Compression Fittings are used to join two or more tubing, thereby extending the un-interrupted flow of content within and creating leak proof tight sealing. 254 SMO Tube Fittings also provides with a stable and strong bond, holding two or more components together in extreme condition and temperatures.

Other Names:- SMO 254 Tube Fittings, UNS S31254 Tube Fittings, WNR 1.4547 Tube Fittings, ASTM B166 Tube Fittings, 6Mo Tube Fittings, SMO Alloy 254 Tube Fittings, SMO Stainless Steel 254 Tube Fittings

254 SMO Forged Fittings

Hex Tubes Inc are proud 254 SMO Forged Fittings suppliers all over the globe. Manufacturing of SMO 254 Forged Fittings is done by various Forming methods or Forging process which includes various shaping operations like applying pressure, hammering, piercing, thrusting out or extruding, bending, rolling, upsetting, fabricating, fusion welding, or by a combination of any of the mentioned operation processes. 254 SMO Forged Fittings are generally made up of pipe, tubing, plates or forgings and are commonly applicable in mechanical fittings and plumbing fittings.

Other Names :- SMO 254 Forged Fittings, UNS S31254 Forged Fittings, WNR 1.4547 Forged Fittings, ASTM B166 Forged Fittings, 6Mo Forged Fittings, SMO Alloy 254 Forged Fittings, SMO Stainless Steel 254 Forged Fittings

254 SMO Flanges

Hex Tubes Inc are proud 254 SMO Flanges suppliers all over the globe. SMO 254 Flanges are further available in 254 SMO Weld-Neck Flanges, WNR 1.4547 SMO 254 Socket-Weld Flanges, 254 SMO UNS S31254 Lap-Joint Flanges, 6Mo Orifice Flanges, ASTM A182 F44 Tongue-Grove Flanges, SMO Alloy 254 Blind Flanges, SMO Stainless Steel 254 Threaded Flanges, UNS S3124 Slip-On Flanges, 254 SMO Spectacle Flanges, UNS S3124 Plate Flanges.

254 SMO Flange is exclusively used to provide additional strength to a joint or weld with tight seal, and to maintain fixed position of two components together. A gasket pre-loaded with 6Mo Flange applies the required mechanical force with the assistance of bolts until the stress is adequate to maintain seal or joint or weld.

Other Names:- 254 SMO Flanges, UNS S31254 Flanges, WNR 1.4547 Flanges, ASTM B166 Flanges, 6Mo Flanges, SMO Alloy 254 Flanges, SMO Stainless Steel 254 Flanges

254 SMO Fasteners

Hex Tubes Inc are proud 254 SMO Fasteners suppliers all over the globe. SMO 254 Fasteners are further available in 254 SMO Nuts Fasteners, 254 SMO Bolts Fasteners, 254 SMO Screws Fasteners, 254 SMO Washers Fasteners.

6Mo Fasteners are primarily used to create a non-permanent joint between two or more components and provides strength along with stability to joints.. This joint created by SMO Alloy 254 Fasteners can be easily dismantled without damaging or harming the components.

Other Names:- SMO 254 Fasteners, UNS S31254 Fasteners, WNR 1.4547 Fasteners, ASTM B166 Fasteners, 6Mo Fasteners, SMO Alloy 254 Fasteners, SMO Stainless Steel 254 Fasteners

254 SMO Bar

Hex Tubes Inc are proud 254 SMO Bars suppliers all over the globe. SMO 254 Bar consist of a bar extended longitudinally in cylindrical shape. These 6Mo Bars are commonly applicable in industrial and commercial applications and are also used to make pipes and tubes.

254 SMO Round Bar is available in different sizes and dimension, different forms like 254 SMO Round Bar, 254 SMO Hex Bar, 254 SMO Rectangle Bar and 254 SMO Square Bar. They are also available as 254 SMO Solid Bar and 254 SMO Hollow Bar (pipes and tubes).

Other Names :- SMO 254 Bars, UNS S31254 Bars, WNR 1.4547 Bars, ASTM B276 Bars, 6Mo Bars, SMO Alloy 254 Bars, SMO Stainless Steel 254 Bars, 254 SMO Steel Round Bars, 254 SMO Round Bars, 254 SMO Steel Hex Bar, 254 SMO Steel Square Bar, 254 SMO Steel Flat Bar, 254 Stainless Steel Bars, 254 Stainless Steel Round Bars, 254 Stainless Steel Hex Bar, 254 Stainless Steel Square Bar, 254 Stainless Steel Flat Bar.

254 SMO Sheetplates

Hex Tubes Inc are proud 254 SMO Sheetplates suppliers all over the globe. A billet of SMO 254 Alloy is put through industrial process of series of hot and cold rolling finally forming into thin flat sheets. These 254 SMO Sheets are actively used in manufacturing of various objects which are formed after fabrication of 254 SMO Sheetplates by cutting and bending ino vaious sizes and shapes.

We have huge stocks of 254 SMO Sheet Plates which are available in various forms like SMO 254 Shim Sheet, SMO 254 Rolled Sheet Coil, SMO 254 Rolled Sheet Strips, SMO 254 Plate, SMO 254 Diamond Plate

Other Names :- SMO 254 Sheetplates, UNS S31254 Sheetplates, WNR 1.4547 Sheetplates, ASTM A240 Sheetplates, 6Mo Sheetplates, SMO Alloy 254 Sheetplates, SMO Stainless Steel 254 Sheetplates.

254 SMO Wiremesh

Hex Tubes Inc are proud 254 SMO Wiremesh suppliers all over the globe. A thin yet strong, cylindrical and flexible strand of thread is pulled out from a billet of SMO 254 alloy. This thread is then woven or welded into each other in a certain pattern to form a mesh or net like structure. This 254 SMO Wiremesh is highly flexible and durable in various conditions.

We at huge inventory of different types of 254 SMO Wire Mesh like 254 SMO Wire , 254 SMO Mesh , 254 SMO Welded Wire Mesh , 254 SMO Woven Wire Mesh , 254 SMO Plain Weave Wire Mesh , 254 SMO Twill Weave Wire Mesh , 254 SMO Dutch Weave Wire Mesh , 254 SMO Crimped Weave Wire Mesh , 254 SMO Three Heddled Weave Wire Mesh , 254 SMO Five Heddled Weave Wire Mesh

Other Names :- SMO 254 Wiremesh, UNS S31254 Wiremesh, WNR 1.4547 Wiremesh, ASTM A240 Wiremesh, 6Mo Wiremesh, SMO Alloy 254 Wiremesh, SMO Stainless Steel 254 Wiremesh.

| Grade | Type | Unified Numbering System (UNS) | Forgings Grades | Werkstoff-nr. | Euronorm | AFNOR | DIN Standards | |

|---|---|---|---|---|---|---|---|---|

| No. | Name | |||||||

| 6Mo grade | 254 SMO | S31254 | F44 | 1.4547 | en 1.4547 | FeMi35Cr20Cu4Mo2 | Z1 CNDU 20.18.06Az | din 1.4547 |

254 SMO Material Properties

- Excellent resistance to pitting and crevice corrosion.

- High resistance to general corrosion.

- High resistance to stress corrosion cracking.

- Higher strength than conventional austenitic stainless steels.

- Good weldability.

Super Austenitic Stainless Steel Applications

- Seawater Equipment such as, seawater cooling, cooling water pipes, ballast water systems, firefighting systems etc.

- Hydraulic and instrumention tubing.

- Equipment in pulp bleaching plants.

- Components in gas cleaning systems.

- Tanks and pipelines for chemicals with high halide contents.

| Elements | Carbon | Chromium | Manganese | Molybdenum | Nickel | Nitrogen | Phosphorus | Silicon | Sulphur |

|---|---|---|---|---|---|---|---|---|---|

| SMO 254 UNS S31254 | 0.02 max | 19.5-20.5 | 1.0 max | 6.0-6.5 | 17.5-18.5 | 0.18-0.22 | 0.03 max | 0.8 max | 0.01 max |

| 0.2% Proof Stress (N/mm2 ) [ksi] minimum | 300 [43.5] |

| Tensile Strength (N/mm2) [ksi] minimum | 650 |

| Elongation (%) minimum | 35 |

| Hardness (HBN) | 270 max |

| Reduction of Cross Section Area (%) | 50 |

| Density (Kg.m-1) | 8000 |

| Magnetic Permeability | <1.05 |

| Young’s Modulus (N/mm2) | 200 x 103 |

| Specific Heat, 20°C (J.Kg-1.°K-1) | 500 |

| Specific Electrical Resistance, 20°C (µO.m) | 0.85 |

| Thermal conductivity, 20°C | 13.5 |

Looking for some more information ?

Get Best Quotes or Send us your Requirement

Documents

- Commercial Invoice including HS Code

- Packing List including number of boxes, net weight, gross weight, Marks & Numbers

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

Testings

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

Packaging

The different ways in which our products are packed are:

- Shrink-wrapped

- Wooden Boxes

- Wooden Pallets

- Wooden Crates

- Carton boxes

Marking

We mark Duplex 2205 as needed with the most suitable & visible marking techniques. Standard Marking System :-

- Manufacturer’s Name or Trademark

- Material Designation

- Size Designation

- Rating Designation

- Melt Designation

- Marking for Identification

Leading Supplier, Manufacturer Exporter

More than 30 years of Experiance

Mill Test Report Provided

In Accordance with EN10204 NACE 3.1, NACE 3.2

Fast Delivery

Warehouse near to Airport & Port.

Efficient & Cost Effective Shipping Services

We Offer EXW – Ex Works, FOB, CFR, CIF, DDU, etc.

Inspection

3rd Party Inspection is Carried out

ISO 9001:2008 Certified

Quality Product

Transparent client dealing, No False Assurance, 100% Fulfillment of Commitments.

Worldwide Exporter

Export to more than 70 Countries Worldwide

Best Price

Competitive pricing is offered